High Quality Data

Our aim is simple. Consistently highest quality images, pin sharp and detailed every time, which is essential for managing your assets through their entire lifecycle. Our proprietary hardware, the AERO Flight Intelligence System flies autonomously without a pre-defined flight path, everything is in real-time, saving our customers from valuable downtime.

AI-Powered Analysis

We fully understand that time and results are important, so all of our acquired data is run through neural networks and AI, finding issues in the quickest time possible. We are continuously growing a vast database to train our AI on, helping us achieve even faster and more accurate results for our clients in the future.

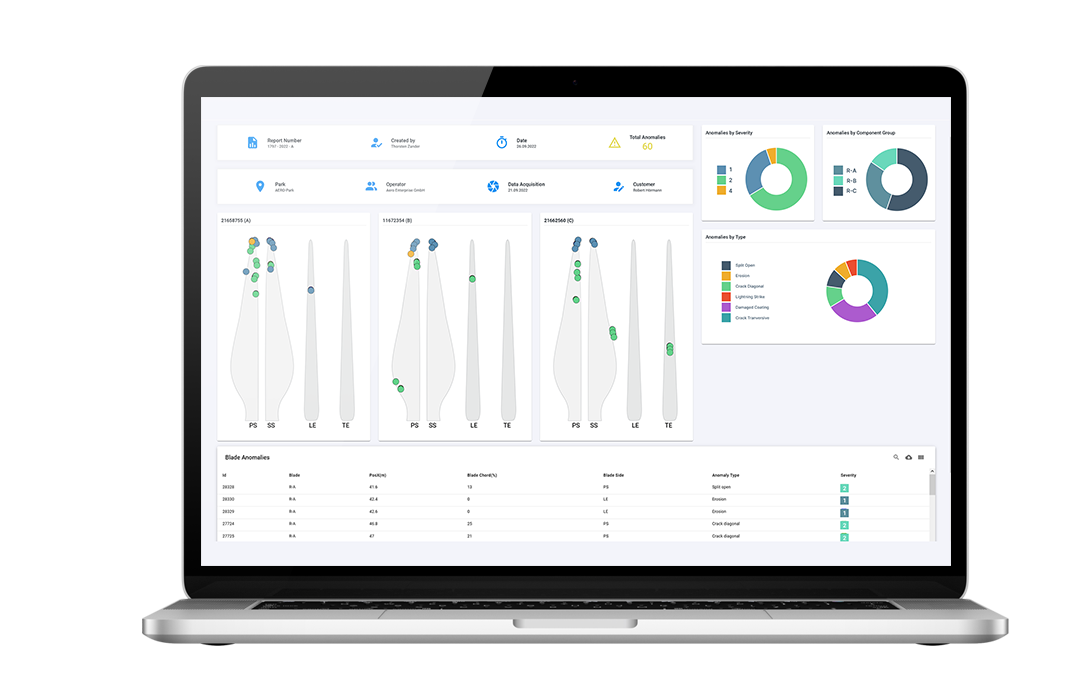

Detailed Reporting

All of our final, detailed, digital reports are compiled from the captured high-resolution images and associated image data, checked and refined though our AERO AI neural networks and run past our experienced Blade Experts to give you the best reports possible, helping you decide when maintenance is needed, and giving you historical, trackable records for the future.