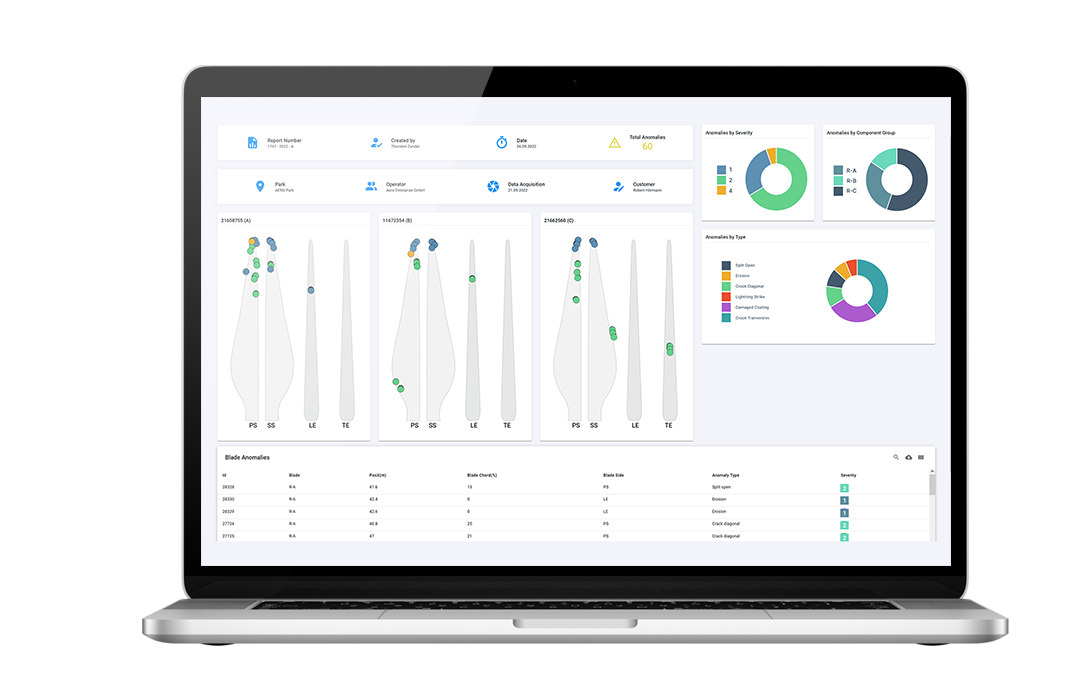

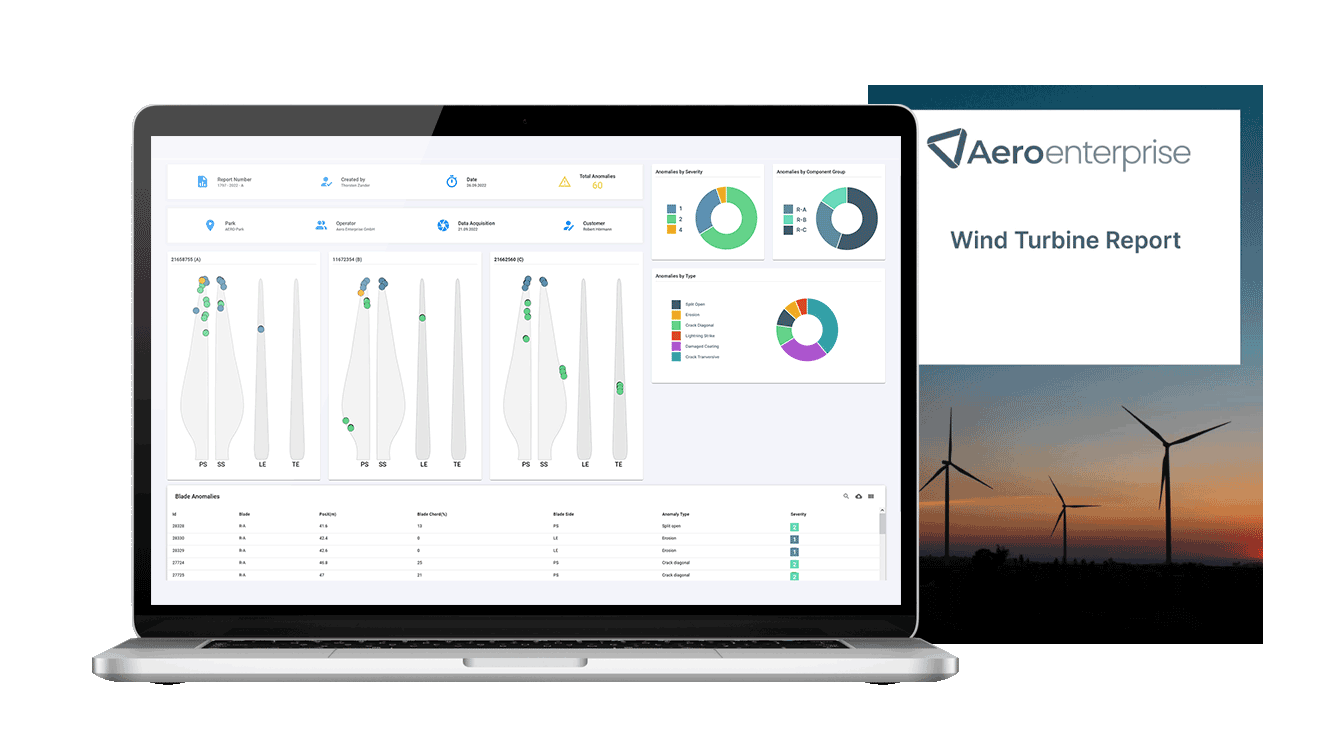

AERO Software

AI-POWERED ANALYSIS / DETAILED REPORTS

We fully understand that time and results are important, so all of our acquired data is run through neural networks and AI finding issues in the quickest time possible. We are continuously growing a vast database to train our AI on, helping us achieve even faster and more accurate reports in the future for our clients.